08 9371 7711

08 9371 7711 Engineering Blog

Engineering Blog

The width of cracks can indicate the severity of the problem. Having an engineer inspect the property to determine the cause of the cracks is a step in the right direction.

In addition to a visual inspection, the engineer may elect to conduct compaction testing to ascertain the bearing capacity of existing foundations. For the typical sandy conditions found across Perth, a Perth Sand Penetrometer (PSP) is generally used.

The instrument itself consists of a 9kg sliding weight suspended on a 2 metre long, blunt ended rod.

The tip of the rod is seated 150mm below the surface; the weight is then lifted and dropped repeatedly from a height of 600mm, driving the rod into the ground.

The results are expressed as the number of blows required to drive the rod a distance of 300mm into the ground. A count of six to eight generally indicates sufficient compaction on a sandy soil.

When a result less than six is recorded, it suggests that the soil under the foundation is not well compacted and therefore may require remedial measures to minimise further settlement.

An effective solution in this situation is Microfine Cement Grout Injection or Chemical Injection as it is sometimes referred.

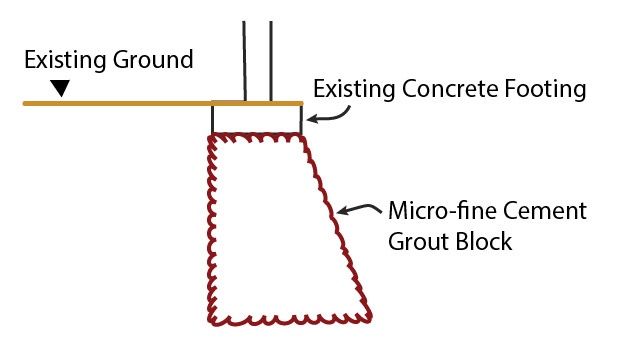

In this method, liquidised Microfine Cement Grout is injected in to the ground, saturating and binding as it fills the voids. When the product hardens a subsoil load bearing block is formed, a typical cross section for the Microfine cement grout block is shown below.

The engineer who conducted the site visit should be able to provide the geometry and extent of the grout block required. Rephrase to emphasis having an engineer design and cerify?

The installation equipment is comprised of three pieces; a spear connected to a delivery hose which is hooked up to mixing equipment mounted on a Utility vehicle. The simplicity and versatility of the equipment makes this technique ideal for confined and hard to access areas and creates minimal disturbance to existing properties.

It should be noted that grouting may not work in all cases. It is highly dependent on the ground conditions encountered on site. Grouting works ideally on sandy conditions, not so well with clay soils. It is advisable that preliminary testing be conducted onsite to ensure grouting is a viable option.

For more information regarding Microfine cement grout visit www.fondex.com.au

Share on Twitter Share on Facebook