08 9371 7711

08 9371 7711 Engineering Blog

Engineering Blog

Mon - Fri, 6:00 - 18:00

Screwpile Bridge Piling application and versatility relates to two catagories:

This screwpiled solution included a reinforced raft mat slab across the piled area. Precast culvets were positioned on top. The design eliminated any future water scour in future rain storms.

Foundation Engineering structural engineers conducted static compression ISL load tests at night to ensure no disruption to the tight installation schedule occured. Load test settlement results confirmed the calculated settlement criteria.

The ability to utilise the original road level platform & the extended reach of the screw pile installing rig configuration provided construction scheduleing flexibility & avoided the need to operate inside the creekbed area..

NEW PEDESTRIAN OVERPASS BRIDGES

Nothing matched the flexibility & manouverability of Screwpile installation rigs. No need for a piling platform. No need for special access ramps. Vertical or raked pile installation is simple. Plus the ability to work above & away from the piled location where required. There was virtually zero traffic disruption at this busy highway intersection off Orrong Road.

Rapid piling installation of screw piles means significant time savings and limited to no traffic disruptions compared to conventional concrete CFA or bored piles.

A huge plus is load testing of installed screw piles can commence immediately regardless of timeframes & site conditions. That combined with the continuous monitoring of predictive installation torques provides for greater assurity of performance across the project.

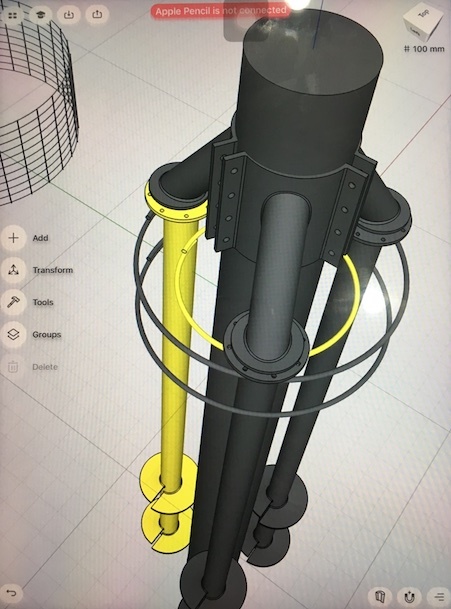

Multiple grouped vertical & raked screw pile installations is not problematic. High torque capacity pendulim rotary hydraulics ensures more than enough screwpile installation torque is available.

REMEDIAL BRIDGE PILING FOUNDATION WORK - TEMPORARY PROP-PILING AND SUPPORTS

Wherever possible remedial piling/foundation tempwork needs to keep traffic flowing. Using screw piles provides the flexibility in designing the best installation approach.

Installation flexibility plus no need for a piling platform provides significant cost & time savings on a project. Where required the screw piles can be uninstalled later.

Bridges that have limited headroom can be overcome by splicing the piles & modifying the installation rig attachments to suit. Just because the rig wont fit under the bridge does not mean the piles cannot be installed. Where access is totally restricted installation can occur through the deck of the bridge.

And when all the remedial works are complete we come back and uninstall the screw piles leaving the site the same as the day we originally arrived.

Screwpiles are cleaned & racked ready for the next project.

At Screwpile Australia we never stop innovating. This recent Retro-Screwpile Refit solution for timber bridge piles suffering from wood-rot has generated interest. For more detailed information contact our engineers at Screwpile Australia or Foundation Engineering Consulting Engineers.